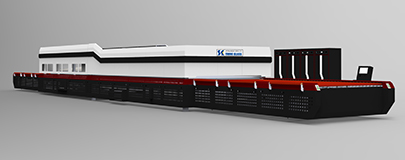

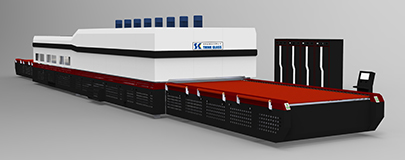

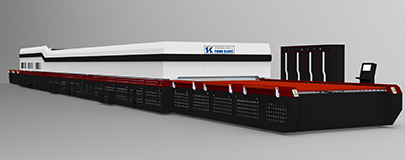

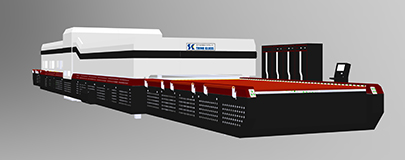

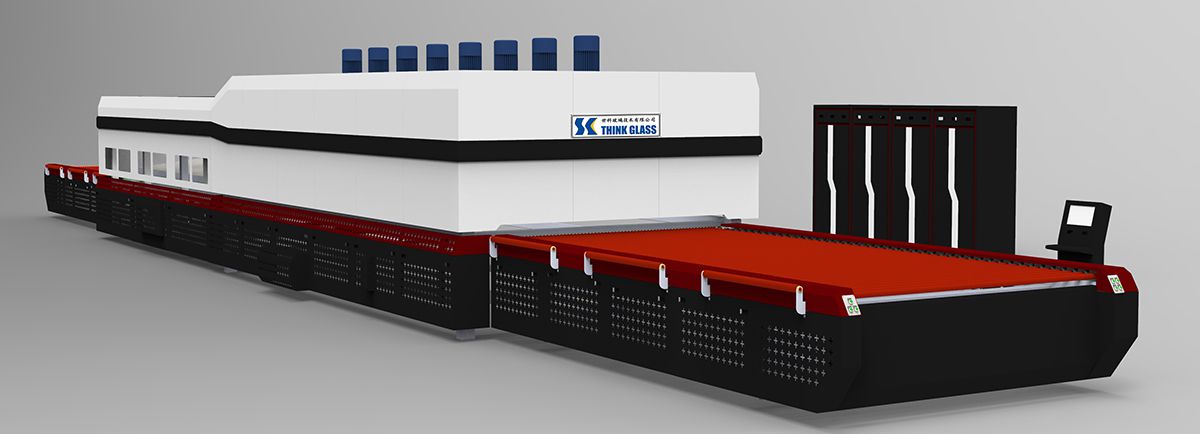

Convection Glass Tempering Furnace

Convection glass tempering furnace is specially designed for processing flat glass and high quality low-E glass, architectural glass, household glass, automobile glass etc. Equipped with a convection heating system, the glass processing machine provides uniform heat, forced heating on glass surfaces, ensuring high surface quality. Featuring a long-lasting structure and stable design, the operating cost of the glass machinery is minimized. When looking for a convection glass tempering furnace integrated into your glass production line, Thinkglass will be your ideal partner.

| Model | Max. Glass Size (mm) | Min. Glass Size (mm) | Glass Thickness Range (mm) | Output (batch/hour) | Installed Capacity (kVA) |

| DLTPG2515 | 2500*1500 | 200*200 | 2.85~15 | 18 | 315 |

| DLTPG4012 | 4000*1250 | 160*160 | 2.85~15 | 18 | 400 |

| DLTPG4015 | 4000*1500 | 200*200 | 2.85~15 | 18 | 500 |

| DLTPG5015 | 5000*1500 | 200*200 | 2.85~15 | 18 | 630 |

| DLTPG3620 | 3660*2000 | 240*240 | 4~19 | 18 | 500 |

| DLTPG4220 | 4200*2000 | 240*240 | 4~19 | 18 | 630 |

| DLTPG3624 | 3660*2440 | 240*240 | 4~19 | 18 | 500 |

| DLTPG4224 | 4200*2440 | 240*240 | 4~19 | 18 | 630 |

| DLTPG5024 | 5000*2440 | 240*240 | 4~19 | 18 | 630 |

| DLTPG6024 | 6000*2440 | 240*240 | 4~19 | 17 | 800 |

| DLTPG8024 | 8000*2440 | 240*240 | 4~19 | 16 | 1250 |

| DLTPG5028 | 5000*2800 | 300*300 | 5~19 | 16 | 800 |

| DLTPG6028 | 6000*2800 | 300*300 | 5~19 | 16 | 1000 |

| DLTPG8028 | 8000*2800 | 300*300 | 5~19 | 16 | 1250 |

| DLTPG5030 | 5000*3000 | 300*300 | 5~19 | 16 | 1000 |

| DLTPG6030 | 6000*3000 | 300*300 | 5~19 | 16 | 1250 |

| DLTPG8030 | 8000*3300 | 350*350 | 5~19 | 16 | 1600 |

- Max. Glass Size (mm): 2500*1500

- Min. Glass Size (mm): 200*200

- Glass Thickness Range (mm): 2.85~15

- Output (batch/hour): 18

- Installed Capacity (kVA): 315

- Max. Glass Size (mm): 4000*1250

- Min. Glass Size (mm): 160*160

- Glass Thickness Range (mm): 2.85~15

- Output (batch/hour): 18

- Installed Capacity (kVA): 400

- Max. Glass Size (mm): 4000*1500

- Min. Glass Size (mm): 200*200

- Glass Thickness Range (mm): 2.85~15

- Output (batch/hour): 18

- Installed Capacity (kVA): 500

- Max. Glass Size (mm): 5000*1500

- Min. Glass Size (mm): 200*200

- Glass Thickness Range (mm): 2.85~15

- Output (batch/hour): 18

- Installed Capacity (kVA): 630

- Max. Glass Size (mm): 3660*2000

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 18

- Installed Capacity (kVA): 500

- Max. Glass Size (mm): 4200*2000

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 18

- Installed Capacity (kVA): 630

- Max. Glass Size (mm): 3660*2440

- Min. Glass Size (mm): 200*200

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 18

- Installed Capacity (kVA): 500

- Max. Glass Size (mm): 4200*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 18

- Installed Capacity (kVA): 630

- Max. Glass Size (mm): 5000*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 18

- Installed Capacity (kVA): 630

- Max. Glass Size (mm): 6000*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 17

- Installed Capacity (kVA): 800

- Max. Glass Size (mm): 8000*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 16

- Installed Capacity (kVA): 1250

- Max. Glass Size (mm): 5000*2800

- Min. Glass Size (mm): 300*300

- Glass Thickness Range (mm): 5~19

- Output (batch/hour): 16

- Installed Capacity (kVA): 800

- Max. Glass Size (mm): 6000*2800

- Min. Glass Size (mm): 300*300

- Glass Thickness Range (mm): 5~19

- Output (batch/hour): 16

- Installed Capacity (kVA): 1000

- Max. Glass Size (mm): 8000*2800

- Min. Glass Size (mm): 300*300

- Glass Thickness Range (mm): 5~19

- Output (batch/hour): 16

- Installed Capacity (kVA): 1250

- Max. Glass Size (mm): 5000*3000

- Min. Glass Size (mm): 300*300

- Glass Thickness Range (mm): 5~19

- Output (batch/hour): 16

- Installed Capacity (kVA): 1000

- Max. Glass Size (mm): 6000*3000

- Min. Glass Size (mm): 300*300

- Glass Thickness Range (mm): 5~19

- Output (batch/hour): 16

- Installed Capacity (kVA): 1250

- Max. Glass Size (mm): 8000*3300

- Min. Glass Size (mm): 350*350

- Glass Thickness Range (mm): 5~19

- Output (batch/hour): 16

- Installed Capacity (kVA): 1600

Notes: The output is calculated based on the 5mm glass with 80% loading efficiency and 100% finished product rate. The production line configurations depend on the glass thickness.

- Jet forced convection is used to heat the top of glass surface, adopts heat balance system on the bottom to adjust the heat quantity in chamber, offering uniform and efficient heating.

- The glass tempering machine is designed with a PID controller for achieving precise temperature control.

- The convection system is used to shorten heating time, improving glass surface quality.

- Adopting stainless steel interior wall causes no contamination to the roller bed.

- The convection is specially designed for processing single silver, double silver and triple silver Low-E glass.

- The heat from the convection is circulated inside the furnace, minimizing thermal losses.

Convection glass tempering furnaces is efficient glass machinery designed for architectural glass, home appliances, glass doors, shower doors, automotive glass and furniture glass production.