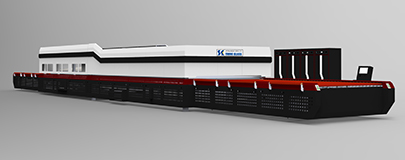

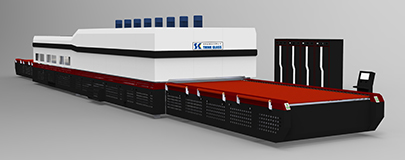

Combined Flat-Bent Glass Tempering Furnace

The glass tempering furnace is used for processing top quality flat and bent tempered glass for automobile, shower rooms, range hoods, household appliances, architecture, etc.

| Model | Max. Glass Size (mm) | Min. Glass Size (mm) | Glass Thickness Range (mm) | Output (batch/hour) | Installed Capacity (kVA) |

| DLTPG2515 | 2500*1500 | 200*200 | 2.85~15 | 18 | 315 |

| DLTPG4012 | 4000*1250 | 160*160 | 2.85~15 | 18 | 400 |

| DLTPG4015 | 4000*1500 | 200*200 | 2.85~15 | 18 | 500 |

| DLTPG5015 | 5000*1500 | 200*200 | 2.85~15 | 18 | 630 |

| DLTPG3620 | 3660*2000 | 240*240 | 4~19 | 18 | 500 |

| DLTPG4220 | 4200*2000 | 240*240 | 4~19 | 18 | 630 |

| DLTPG3624 | 3660*2440 | 240*240 | 4~19 | 18 | 500 |

| DLTPG4224 | 4200*2440 | 240*240 | 4~19 | 18 | 630 |

| DLTPG5024 | 5000*2440 | 240*240 | 4~19 | 18 | 630 |

| DLTPG6024 | 6000*2440 | 240*240 | 4~19 | 17 | 800 |

| DLTPG8024 | 8000*2440 | 240*240 | 4~19 | 16 | 1250 |

| DLTPG5028 | 5000*2800 | 300*300 | 5~19 | 16 | 800 |

| DLTPG6028 | 6000*2800 | 300*300 | 5~19 | 16 | 1000 |

| DLTPG8028 | 8000*2800 | 300*300 | 5~19 | 16 | 1250 |

| DLTPG5030 | 5000*3000 | 300*300 | 5~19 | 16 | 1000 |

| DLTPG6030 | 6000*3000 | 300*300 | 5~19 | 16 | 1250 |

| DLTPG8030 | 8000*3300 | 350*350 | 5~19 | 16 | 1600 |

- Max. Glass Size (mm): 2500*1500

- Min. Glass Size (mm): 200*200

- Glass Thickness Range (mm): 2.85~15

- Output (batch/hour): 18

- Installed Capacity (kVA): 315

- Max. Glass Size (mm): 4000*1250

- Min. Glass Size (mm): 160*160

- Glass Thickness Range (mm): 2.85~15

- Output (batch/hour): 18

- Installed Capacity (kVA): 400

- Max. Glass Size (mm): 4000*1500

- Min. Glass Size (mm): 200*200

- Glass Thickness Range (mm): 2.85~15

- Output (batch/hour): 18

- Installed Capacity (kVA): 500

- Max. Glass Size (mm): 5000*1500

- Min. Glass Size (mm): 200*200

- Glass Thickness Range (mm): 2.85~15

- Output (batch/hour): 18

- Installed Capacity (kVA): 630

- Max. Glass Size (mm): 3660*2000

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 18

- Installed Capacity (kVA): 500

- Max. Glass Size (mm): 4200*2000

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 18

- Installed Capacity (kVA): 630

- Max. Glass Size (mm): 3660*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 18

- Installed Capacity (kVA): 500

- Max. Glass Size (mm): 4200*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 18

- Installed Capacity (kVA): 630

- Max. Glass Size (mm): 5000*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 18

- Installed Capacity (kVA): 630

- Max. Glass Size (mm): 6000*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 17

- Installed Capacity (kVA): 800

- Max. Glass Size (mm): 8000*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 16

- Installed Capacity (kVA): 1250

- Max. Glass Size (mm): 5000*2800

- Min. Glass Size (mm): 300*300

- Glass Thickness Range (mm): 5~19

- Output (batch/hour): 16

- Installed Capacity (kVA): 800

- Max. Glass Size (mm): 6000*2800

- Min. Glass Size (mm): 300*300

- Glass Thickness Range (mm): 5~19

- Output (batch/hour): 16

- Installed Capacity (kVA): 1000

- Max. Glass Size (mm): 8000*2800

- Min. Glass Size (mm): 300*300

- Glass Thickness Range (mm): 5~19

- Output (batch/hour): 16

- Installed Capacity (kVA): 1250

- Max. Glass Size (mm): 5000*3000

- Min. Glass Size (mm): 300*300

- Glass Thickness Range (mm): 5~19

- Output (batch/hour): 16

- Installed Capacity (kVA): 1000

- Max. Glass Size (mm): 6000*3000

- Min. Glass Size (mm): 300*300

- Glass Thickness Range (mm): 5~19

- Output (batch/hour): 16

- Installed Capacity (kVA): 1250

- Max. Glass Size (mm): 8000*3300

- Min. Glass Size (mm): 350*350

- Glass Thickness Range (mm): 5~19

- Output (batch/hour): 16

- Installed Capacity (kVA): 1600

Notes: The output is calculated based on the 5mm glass with 80% loading efficiency and 100% finished product rate. The production line configurations depend on the glass thickness.

- Horizontal bent or vertical bent is optional;

- Exact formation and good roundness for tempered glass is ensured due to computerized radian adjustment;

- Irregular shape glass can be produced due to various radian adjustment methods;

- Radian formed is very stable due to dual motor synchronous drive;

- Fully automated glass tempering for flat and bent glass;

- Suitable for tempering various glass types such as clear glass, colored glass, reflective glass;

- Glass can be bent to the required form without mould, ensuring easy and efficient production;

- Low energy consumption is ensured because of top quality insulation material and special heat-preservation layer;

- High speed and perfect glass tempering for any glass factory;

- Features high automation and easy operation thanks to powerful control software;

The glass processing equipment is suitable for tempering various glass types such as clear glass, colored glass, reflective glass. The tempered glass has found wide applications in the wall curtains, automobile, shower rooms, range hoods, showcases, etc.

-

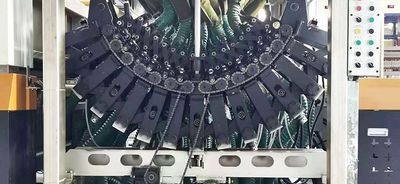

- Computerized Control System

All processing parameters are allowed to be easily preset and changed throughout the process via the user-friendly human-machine interface. The parameters for glass of various thickness are simply saved as orders. In addition, settings can be saved for future use, including glass type and glass thickness. All these enables easy machine operation.